The importance of concrete prep geometry for post-tension repair

The persistent deterioration of previously repaired post-tensioned concrete, particularly around tendon anchors, is a developing phenomenon that some in the post-tensioning and structural repair communities have not yet fully recognized. The underlying cause of failure of these prior repairs can often be attributed to the use of incorrect repair demolition geometry that leads to the development of a highly active corrosion cell, which results in accelerated corrosion of the embedded mild steel reinforcement and the post-tensioning. This is an important issue because the potential loss of post-tensioning can compromise the integrity of a structure.

Photo: Old patching material is clearly visible, exposing advanced corrosion of embedded steel.

Photo: This failed slab edge patch was applied to the surface of the anchors without fully excavating the damaged area.

Consequences of incorrect repair geometry

When corrosion damaged concrete is removed only from the face of the anchors and surrounding rebar, this causes the embedded steel elements to become sandwiched between the existing concrete that remains and the new concrete patching mortar. The resulting extreme differential between the properties of the two concrete materials creates a macroscopic corrosion cell with increased corrosion potential that causes the embedded steel to continue to corrode at a rapid rate. The International Concrete Repair Institute (ICRI) describes this phenomenon as the Anodic Ring or Halo Effect. They attribute this accelerated corrosion to the differential in electrical potential that’s created “between the chloride contaminated or low pH existing concrete and the chloride-free or high pH repair material”.

Demolition geometry impact on post-tensioning

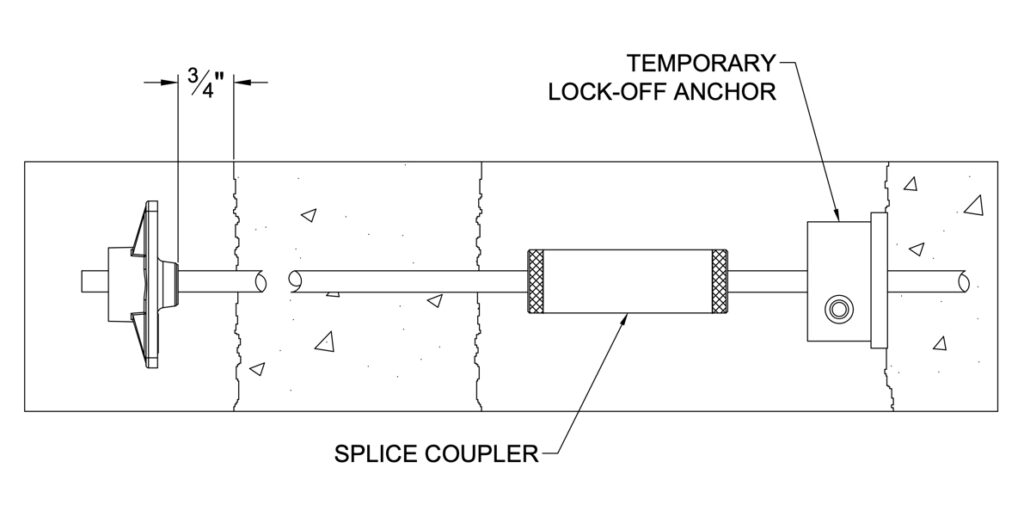

When corrosion damage extends into the mild steel reinforcement located around and behind the tendon anchors, the concrete repair excavation protocol recommended by the ICRI can require the removal of concrete into the high-stress zone that exists behind the tendon terminal anchors. Therefore, in order to perform this work safely, the tension load on existing anchors must be temporarily relocated using a specialty lock-off anchor that is installed beyond the high-stress zone.

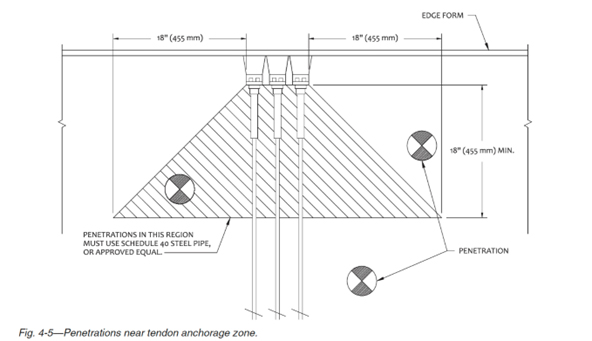

Image: The Post-Tensioning Institute recognizes the high-stress zone that exists behind terminal anchors.

Image: Note that the ICRI required excavation extends into the high-stress zone behind the anchor.

What is the correct repair geometry?

When performing concrete structural repairs, the ICRI “Guide for Surface Preparation for the Repair of Deteriorated Concrete Resulting from Reinforcing Steel Corrosion” recommends a “ minimum of 0.75 in. (19 mm) clearance between exposed reinforcing steel and surrounding concrete or 0.25 in. (6 mm) larger than the coarse aggregate in the repair material, whichever is greater.”

Consequences of concrete patch failures

Ongoing corrosion of embedded mild steel around the post-tension anchorages will result in cracking and spalling of the concrete coverage in this critical area. These cracks will permit water to penetrate deeply into the slab and down to the level of the post-tensioning, which can find its way directly into the cables through any disruptions in the tendon sheathing. When this is allowed to happen, it substantially increases the likelihood of corrosion of the steel cable and can ultimately result in a failure of the tendon.

Photo: Shown is a fully excavated slab edge per ICRI requirements with tendon lock-off installed.

Photo: Tendon end that shows cable corrosion due to water intrusion into the cable sheathing.

Conclusion

While there are financial considerations associated with including the effected post-tensioning in a concrete repair project, the consequences of not doing the work correctly can be exponentially worse. Trying to undertake concrete repairs without properly addressing the existing post-tensioning can create life safety hazards for those involved in the repairs. Additionally, repairs that lack suitable durability will need to be redone at some point in the future. Lastly, it has been observed during the repair of structures that have not followed proper concrete repair protocols, that the increased corrosion potential has an extremely detrimental effect on the post-tensioning within the repair areas and can lead to significant loss of structural reinforcement.

Cited References/Images

PTI M-10: Unbonded Tendon Committee, “Field Procedures Manual for Unbonded Single Strand Tendons (PTI M10.3-16),” Post-Tensioning Institute, Farmington Hills, MI, 2016, 14pp.

Surface Preparation Committee, “Guide for Surface Preparation for the Repair of Deteriorated Concrete Resulting from Reinforcing Steel Corrosion (Guideline No. 310.1R–2008),” International Concrete Repair Institute, Des Plaines, IL, 2008, 2-4pp.

For more information:

Please email us at info@GenBuild.net

Click below the link to download the pdf file: