Repair Of Bundled Unbonded Tendons

The repair of tightly bundled unbonded monostrand tendons is one of the most challenging types of post-tensioned repairs. This is due to not only the extremely high tension loads associated with anchoring multiple tendons, but the proximity of the cables relative to each other also creates obstacles for the use of conventional temporary anchor equipment. These repairs can be hazardous and require a high level of contracting expertise, as well as thorough planning and sequencing strategies to perform this work safely. A failure during the repair can be hazardous to personal safety, and the unplanned loss of post-tensioning on a localized portion of the structure could be catastrophic.

While there are any number of location specific considerations that need to be accounted for during an unbonded tendon repair, the primary focus of this discussion will be the equipment limitations that exist within the post-tensioning industry for the repair of tightly bundled tendons.

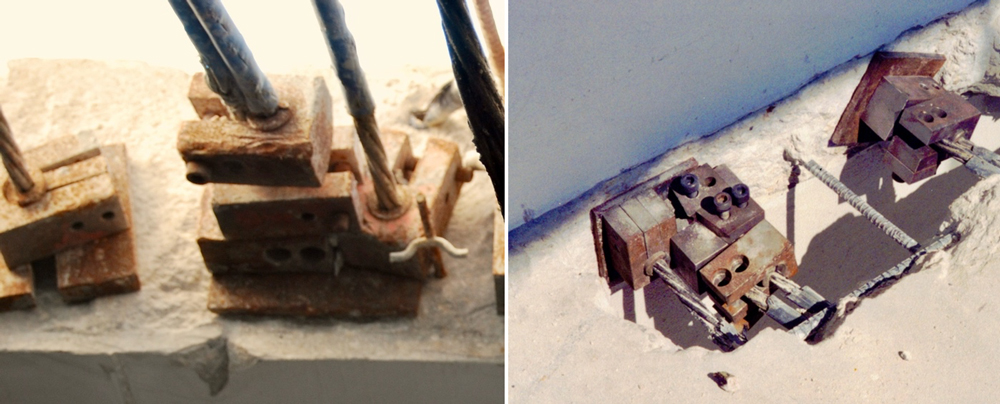

Photo: Groups of bundled tendons in a slab band line that is under repair.

Equipment limitations

Unlike individual tendons that are evenly spaced apart from each other, bundled groups of cables may be spaced as tightly as 1/2” to 5/8” on center. When it becomes necessary to transfer the tendon force from the permanent terminal anchorage to a temporary anchor, the device used is referred to as a troubleshooting anchor but is more commonly known as a lock-off anchor. These temporary anchors have been used in post-tensioning for decades, but the traditional lock-off design is limited for use only with single cables. This is due to the structural imitations of the lock-off anchor design because it’s based on the use of typical 1” diameter round wedges. Additionally, the lock-off also requires steel anchor components of sufficient size to withstand and distribute the potential 33kip tension load that will be applied to the anchor. These anchor size limitations often result in field installation problems due to conflicts with other adjoining tendons or mild reinforcement.

Photo: Traditional single cable lock-off anchors.

Improvised solutions using single cable lock-offs

Unfortunately, these equipment limitations have been an obstacle for the post-tensioning industry in the development of a multi-cable lock-off anchor that can safely and effectively secure bundled cables. All too often, this has forced contractors to improvise the use multiple single cable lock-off anchors that are stacked together in an effort to secure multiple bundled cables.

When multiple individual lock-offs are used to secure tightly bundled tendons, it’s not only challenging, but it can also create potentially unstable and unsafe situations. If any piece of the lock-off puzzle fails, it will result in an instantaneous loss of support for the affected tendons. Additionally, it could also create projectiles out of the lock-off components, as well as any concrete that ruptures because of the failure. Not only is this a hazard to personal safety, but it could also lead to a dangerous compromise of structural integrity.

Photos: Bundled cables secured using single cable lock-off anchor that are stacked together.

Multi-cable lock-off solution

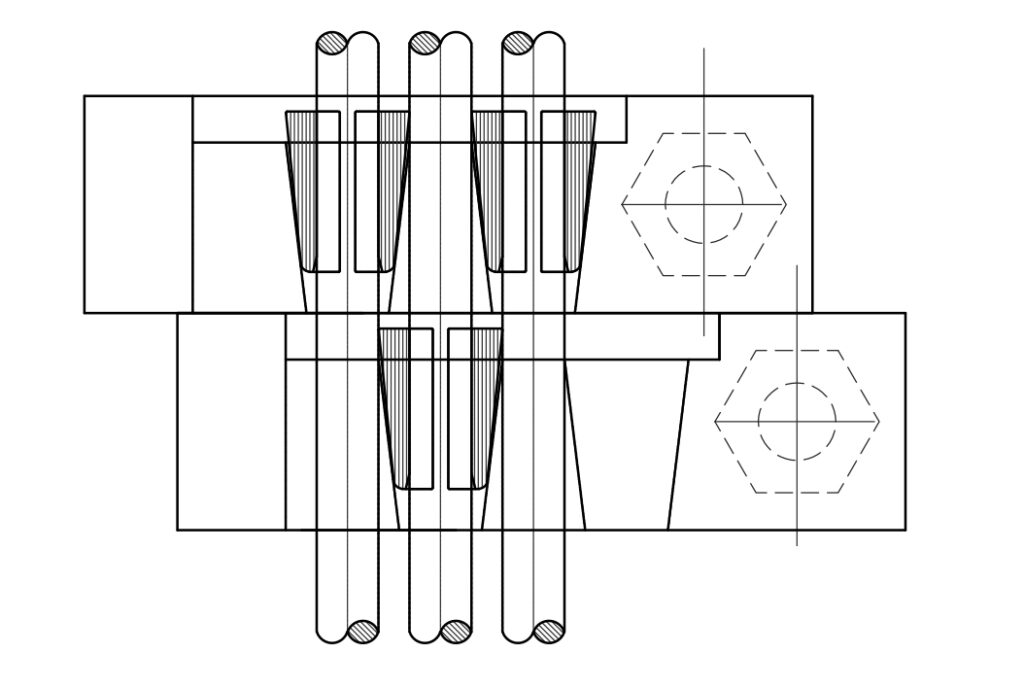

In 2016, the owner of our company was issued a U.S. Patent for a new lock-off anchor that was specifically designed for use in securing bundled tendons. However, while it was utilized exclusively as an in-house resource, it wasn’t made commercially available to the post-tensioning industry until 2020. This device utilizes several design concepts that allow it to safely secure multiple tendons. Given the limitations of using the standard 1” wedge design, this lock-off spaces the wedge cavities apart, with room between each set of wedges for a cable to pass through the anchor, which allows the anchor to secure every other cable. The wedge cavity is also recessed on the anchor face, which permits the anchors to be stacked on top of each other.

Image: Multi-Cable Lock-Off anchor cross section that shows how it functions to secure multiple cables.

Limitations of the Multi-cable Lock-off anchor

One of the limitations of the new lock-off anchor is that it still uses the traditional round wedges, which interferes with the anchors ability to secure cables that are too tightly spaced together. This requires the anchor installer to locate the lock-off where the bundled cables are sufficiently spread apart, or to create the necessary spacing between the cables to install the lock-off anchor.

Photo: Field use of photo of the Patented Multi-Cable Lock-Off anchor used to secure bundled cables

Development of the new Flat Wedge Lock-off anchor

Our company has worked to overcome the round wedge obstacle and developed an entirely new lock-off anchor technology based on the use of a purpose made flat wedge design. This Patent Pending anchor uses a new wedge design that is only 5/8” wide, that are rectangular rather than round, and which allows them to be installed side by side. This overcomes the wedge interference problems caused by using traditional round wedges. Another key design feature is that these anchors utilize an elongated slot wedge cavity, instead of the traditional cone shaped cavity, which permits the flat wedges to be installed flush against each other. This results in an allowable center to center spacing between the cables of as little as 5/8”, depending on the thickness of the sheathing utilized on the cable.

Another design feature of the Flat Wedge Lock-off is that the wedge cavity is recessed, which permits the anchors to be stacked on top of each other, without any bearing interference from the wedges in the bottom anchor. Additionally, unlike traditional round wedges that are limited to a single use, the flat wedge design and metallurgy has proven to be durable and will withstand the repeated use of multiple stressing cycles.

Photo: Patent Pending Flat Wedge Lock-Off provides versatile anchor design to secure multiple cables

Photo: The Flat Wedge Lock-Off anchors are available in several different configurations

Conclusion

The repair of tightly bundled tendons remains one of the most difficult repairs that one may face for the reasons stated throughout this bulletin. While the industry has made little progress in the development of lock-off anchor technology over the past few decades, there are finally several new products that are making their way into the market that can help make these repairs easier and safer. However, regardless of whatever equipment is utilized, the nature of this work requires that all parties involved should have sufficient experience to perform these repairs safely.

For more information:

Please email us at info@GenBuild.net

Flat Wedge Lock-off anchors can be found at www.Post-TensionProducts.com, and are available in 2 cable and 3 cable configurations.